616,Udyog Vihar, Ph-V, Gurgaon, India

![]() ISO

ISO 9001-2000

ISO

ISO 9001-2000

616,Udyog Vihar, Ph-V

Contact Person: Mr. amit Kumar

Gurgaon, Haryana,

India

Ph: +x xxxxxxxxxx

Email: xxxxxx@xxxx

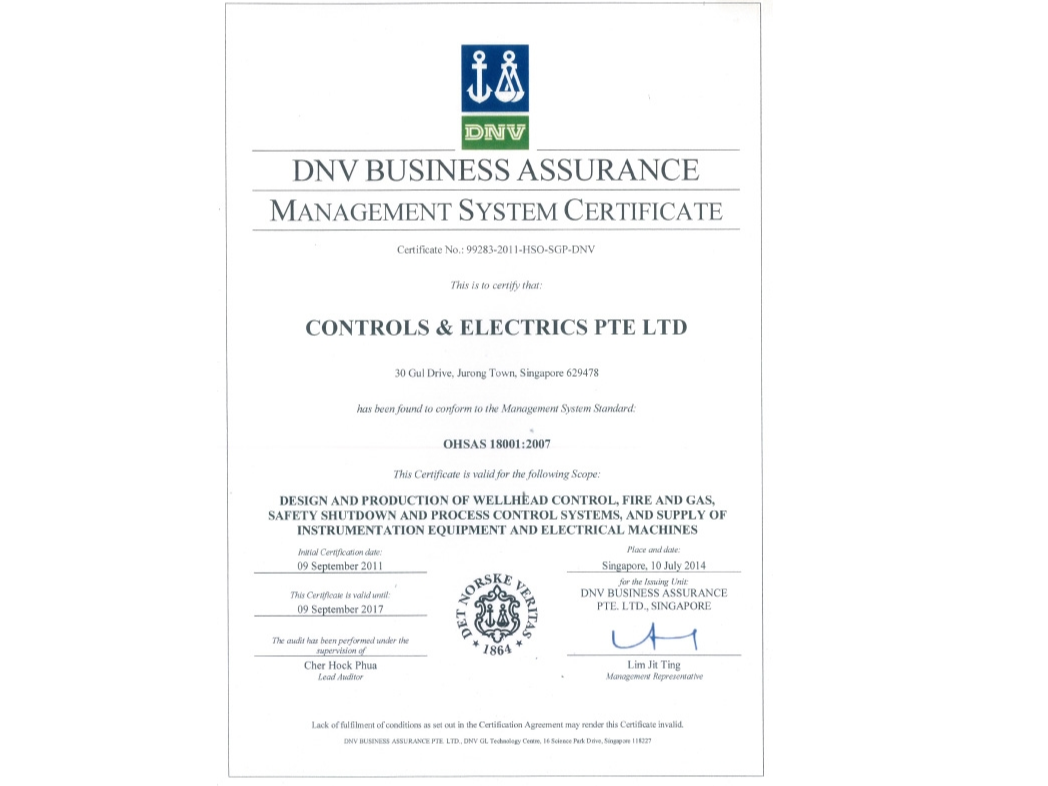

Controls & Electrics Pte. Ltd.

30 Gul Drive

Singapore ,

629478, Singapore

Ph: +x xxxxxxxxxx

Email: xxxxxx@xxxx

P.O.Box-3949

Abu Dhabi, UAE,

United Arab Emirates

Ph: +x xxxxxxxxxx

( Click here to view email and contact)

616,Udyog Vihar, Ph-V

Contact Person : Mr. amit Kumar

Gurgaon, Haryana,

India

Ph: +x xxxxxxxxxx

Email: xxxxxx@xxxx

Controls & Electrics Pte. Ltd.

30 Gul Drive

Contact Person :

Singapore ,

629478, Singapore

Ph: +x xxxxxxxxxx

Email: xxxxxx@xxxx

P.O.Box-3949

Contact Person :

Abu Dhabi, UAE,

United Arab Emirates

Ph: +x xxxxxxxxxx

<h2>Well Test Panel Specifications:</h2> <ul> <li>Working Pressure in psig - 6000, 10000, 15000, 20000</li> <li>Hydraulic Fluid - Mineral Oil, Water based Glycol</li> <li>Tank Size - 30 - 50 liters</li> <li>Logic & Pump Supply - Pneumatic typical 100 psig</li> <li>Pneumatic Pump - Single c/w Hand lever</li> <li>Number of Shutdown Valves - 2 or 3</li> <li>Output Connections - 3/8" NPTF c/w quick connectors</li> <li>Fusible Loop - 1 no</li> <li>ESD Loop - 1 no</li> <li>Hi-Lo Pressure Pilot Loop - 1 no c/w supply to the loop</li> <li>Enclosure - NEMA 4X</li> </ul>

<h2>Standard Features</h2> <ul> <li>Provides Accountability to ISO9000</li> <li>Controls 1 to 4 Additive Lines</li> <li>Comprehensive Alarms for Over/Under Injections</li> <li>Fully Programmable</li> <li>Central Computer Interface for Reports/Logs</li> <li>Multiple Injectors on same Line or</li> <li>Control Injection for up to 4 lines at a Load Spot</li> <li>Weights & Measures Approval</li> <li>Hazardous Area Approvals</li> </ul>

<p>Comprehensive engineering services & documentation are provided for all systems supplied by us including 3-D drawngs where required. Typical documentation includes:</p> <p>Functional Design Specifications<br />Detailed Engineering<br />Instrument Data Sheets<br />GA Drawings<br />Loop Diagrams<br />Logic Diagrams<br />Application Software Development<br />Interconnection /Hook-up Diagrams</p>

<p>Training forms an important & integral part of our value-added services. We strongly believe that well-trained Operations Staff are crucial to the successful start-up, operation and maintenance of any control system. After all, a control system - though valued at only a few percents of the overall cost- is the combined HEART & BRAIN of the process/plant.</p> <p>Both classroom and hands-on training are provided to customer's engineers to ensure that they are up to a level where they can not only handle the equipment with confidence but are adequately familiar to provide at least up to the 1st level of support in the unlikely event of a system malfunction.</p> <p>Apart from standard training programmes, customer and project-specific training tailored to meet individual or group needs are provided both in the factory and subsequently on the job site. Programs are available for both electronic and hydraulic control systems.</p>

<h2>Standard Features</h2> <ul> <li>API 14B /14C Compliant Design</li> <li>Adjustable Hydraulic Pressure (S.I.T.P + 1000 psig)</li> <li>Internally charged ESD loop</li> <li>Adjustable Time Delay</li> <li>Air or Natural Gas Operation</li> <li>Sour Gas Operation Option</li> <li>Manual Well Shut-in</li> <li>External ESD Monitoring</li> <li>Remote ESD/RTU Interface</li> <li>Integrated or Separate Hydraulic Power Unit with Manual Lever or Standby Hand pump</li> <li>Modularized Multi-well Panels</li> <li>Independent Opening/Closing of Each Well</li> <li>Pneumatic, Hydraulic or Electronic Logic</li> <li>Sequential Opening and Closing of Valves under Equalized Conditions</li> <li>FIRST-UP Audio Visual Alarm</li> <li>Automatic Start-up Bypass for Low Process Inputs</li> <li>Manual By-Pass for All Inputs</li> </ul>

<p>The HPU can be integrated into the common section of the panel complete with pneumatic/electric driven pumps, accumulators, reservoirs, thermal and pressure relief optimally sized to provide actuating power to all hydraulically operated shutdown valves.</p> <p>Alternatively, the HPU can be a separate stand-alone skid mounted unit. Accumulators are available in different materials of construction to suit the environment.</p>

<p>Standard Features</p> <ul> <li>Skid Structure: ASME/BS</li> <li>Over pressure protection:</li> <li>API 520</li> <li>Storage Tanks: </li> <li>ASME sec VIII Div 1 and using Roark & Young stress/strain formulae.</li> <li>Dosing Pumps : API675</li> <li>Control System:</li> <li>Interface with RTU, PCS, ESD systems.</li> <li>Testing:</li> <li>EN12079 for offshore.</li> </ul>

<p><span style="color: #333333; font-family: 'Roboto Slab', serif; font-size: 14px;">Standard Features</span></p> <ul> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">TUV (AK6 SIL 3) approved Hardware</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Redundant Controllers</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Redundant Power Supplies</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Intelligent Redundant I/O</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Redundant Communications</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">IEC 1131-3 Compliant Configuration Software</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">High Availability</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">High Reliability</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Advanced Diagnostics</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Extensive Algorithm Library</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">High Speed Redundant Highway</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Line Testing for Short and Open Circuits</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Corrosion Protected</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">RFI & EMI Immunity</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Input Isolation</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Input Bypass/Maintenance</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Over-ride via Matrix Panel or Graphical User Interface</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Alarm Management</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Sequential Events Recording (3ms resolution) Option</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">User Friendly HMI</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Windows platform</span></li> </ul>

<p>From FPSOs and Production platforms to tunnels and buildings, C&E provides fire and gas detection, alarm and protection systems. Using state-of-the-art discrete as well as addressable detectors and transmitters, systems are configured to operate in conjunction with controller cards, addressable fire panels and/or plcs. Where required, we also supply the FM 200 or other extinguishing systems as part of the package.</p> <p>Fire & Gas Systems are engineered and supplied on the stand-alone basis or as part of an integrated ESD and/or Process Control System.</p> <p>Notable systems in successful operation include the F&G System for Saudi Aramco's ZULUF GOSP-2 Production Complex which, at 1.2 million/barrels per day, is the largest single such complex anywhere in the world. A significant number of FPSOs and production platforms worldwide are also protected by F&G systems designed and implemented by C & E.</p>

<p><strong>Specifications</strong></p> <ul> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Water and Waste Water Treatment Complexes</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Off-shore Well & Production Complexes</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Geothermal Power Generation</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Rayon Production</span></li> </ul>

<h2>Well Test Panel Specifications:</h2> <ul> <li>Working Pressure in psig - 6000, 10000, 15000, 20000</li> <li>Hydraulic Fluid - Mineral Oil, Water based Glycol</li> <li>Tank Size - 30 - 50 liters</li> <li>Logic & Pump Supply - Pneumatic typical 100 psig</li> <li>Pneumatic Pump - Single c/w Hand lever</li> <li>Number of Shutdown Valves - 2 or 3</li> <li>Output Connections - 3/8" NPTF c/w quick connectors</li> <li>Fusible Loop - 1 no</li> <li>ESD Loop - 1 no</li> <li>Hi-Lo Pressure Pilot Loop - 1 no c/w supply to the loop</li> <li>Enclosure - NEMA 4X</li> </ul>

<h2>Standard Features</h2> <ul> <li>Provides Accountability to ISO9000</li> <li>Controls 1 to 4 Additive Lines</li> <li>Comprehensive Alarms for Over/Under Injections</li> <li>Fully Programmable</li> <li>Central Computer Interface for Reports/Logs</li> <li>Multiple Injectors on same Line or</li> <li>Control Injection for up to 4 lines at a Load Spot</li> <li>Weights & Measures Approval</li> <li>Hazardous Area Approvals</li> </ul>

<p>Comprehensive engineering services & documentation are provided for all systems supplied by us including 3-D drawngs where required. Typical documentation includes:</p> <p>Functional Design Specifications<br />Detailed Engineering<br />Instrument Data Sheets<br />GA Drawings<br />Loop Diagrams<br />Logic Diagrams<br />Application Software Development<br />Interconnection /Hook-up Diagrams</p>

<p>Training forms an important & integral part of our value-added services. We strongly believe that well-trained Operations Staff are crucial to the successful start-up, operation and maintenance of any control system. After all, a control system - though valued at only a few percents of the overall cost- is the combined HEART & BRAIN of the process/plant.</p> <p>Both classroom and hands-on training are provided to customer's engineers to ensure that they are up to a level where they can not only handle the equipment with confidence but are adequately familiar to provide at least up to the 1st level of support in the unlikely event of a system malfunction.</p> <p>Apart from standard training programmes, customer and project-specific training tailored to meet individual or group needs are provided both in the factory and subsequently on the job site. Programs are available for both electronic and hydraulic control systems.</p>

<h2>Standard Features</h2> <ul> <li>API 14B /14C Compliant Design</li> <li>Adjustable Hydraulic Pressure (S.I.T.P + 1000 psig)</li> <li>Internally charged ESD loop</li> <li>Adjustable Time Delay</li> <li>Air or Natural Gas Operation</li> <li>Sour Gas Operation Option</li> <li>Manual Well Shut-in</li> <li>External ESD Monitoring</li> <li>Remote ESD/RTU Interface</li> <li>Integrated or Separate Hydraulic Power Unit with Manual Lever or Standby Hand pump</li> <li>Modularized Multi-well Panels</li> <li>Independent Opening/Closing of Each Well</li> <li>Pneumatic, Hydraulic or Electronic Logic</li> <li>Sequential Opening and Closing of Valves under Equalized Conditions</li> <li>FIRST-UP Audio Visual Alarm</li> <li>Automatic Start-up Bypass for Low Process Inputs</li> <li>Manual By-Pass for All Inputs</li> </ul>

<p>The HPU can be integrated into the common section of the panel complete with pneumatic/electric driven pumps, accumulators, reservoirs, thermal and pressure relief optimally sized to provide actuating power to all hydraulically operated shutdown valves.</p> <p>Alternatively, the HPU can be a separate stand-alone skid mounted unit. Accumulators are available in different materials of construction to suit the environment.</p>

<p>Standard Features</p> <ul> <li>Skid Structure: ASME/BS</li> <li>Over pressure protection:</li> <li>API 520</li> <li>Storage Tanks: </li> <li>ASME sec VIII Div 1 and using Roark & Young stress/strain formulae.</li> <li>Dosing Pumps : API675</li> <li>Control System:</li> <li>Interface with RTU, PCS, ESD systems.</li> <li>Testing:</li> <li>EN12079 for offshore.</li> </ul>

<p><span style="color: #333333; font-family: 'Roboto Slab', serif; font-size: 14px;">Standard Features</span></p> <ul> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">TUV (AK6 SIL 3) approved Hardware</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Redundant Controllers</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Redundant Power Supplies</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Intelligent Redundant I/O</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Redundant Communications</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">IEC 1131-3 Compliant Configuration Software</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">High Availability</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">High Reliability</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Advanced Diagnostics</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Extensive Algorithm Library</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">High Speed Redundant Highway</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Line Testing for Short and Open Circuits</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Corrosion Protected</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">RFI & EMI Immunity</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Input Isolation</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Input Bypass/Maintenance</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Over-ride via Matrix Panel or Graphical User Interface</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Alarm Management</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Sequential Events Recording (3ms resolution) Option</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">User Friendly HMI</span></li> <li><span style="background-color: initial; font-size: 13px; color: #333333; font-family: 'Roboto Slab', serif;">Windows platform</span></li> </ul>

Comprehensive engineering services & documentation are provided for all systems supplied by us including 3-D drawngs where required. Typical documentation includes:

Functional Design Specifications

Detailed Engineering

Instrument Data Sheets

GA Drawings

Loop Diagrams

Logic Diagrams

Application Software Development

Interconnection /Hook-up Diagrams

Training forms an important & integral part of our value-added services. We strongly believe that well-trained Operations Staff are crucial to the successful start-up, operation and maintenance of any control system. After all, a control system - though valued at only a few percents of the overall cost- is the combined HEART & BRAIN of the process/plant.

Both classroom and hands-on training are provided to customer's engineers to ensure that they are up to a level where they can not only handle the equipment with confidence but are adequately familiar to provide at least up to the 1st level of support in the unlikely event of a system malfunction.

Apart from standard training programmes, customer and project-specific training tailored to meet individual or group needs are provided both in the factory and subsequently on the job site. Programs are available for both electronic and hydraulic control systems.

The HPU can be integrated into the common section of the panel complete with pneumatic/electric driven pumps, accumulators, reservoirs, thermal and pressure relief optimally sized to provide actuating power to all hydraulically operated shutdown valves.

Alternatively, the HPU can be a separate stand-alone skid mounted unit. Accumulators are available in different materials of construction to suit the environment.

Standard Features

Standard Features

From FPSOs and Production platforms to tunnels and buildings, C&E provides fire and gas detection, alarm and protection systems. Using state-of-the-art discrete as well as addressable detectors and transmitters, systems are configured to operate in conjunction with controller cards, addressable fire panels and/or plcs. Where required, we also supply the FM 200 or other extinguishing systems as part of the package.

Fire & Gas Systems are engineered and supplied on the stand-alone basis or as part of an integrated ESD and/or Process Control System.

Notable systems in successful operation include the F&G System for Saudi Aramco's ZULUF GOSP-2 Production Complex which, at 1.2 million/barrels per day, is the largest single such complex anywhere in the world. A significant number of FPSOs and production platforms worldwide are also protected by F&G systems designed and implemented by C & E.

Comprehensive engineering services & documentation are provided for all systems supplied by us including 3-D drawngs where required. Typical documentation includes:

Functional Design Specifications

Detailed Engineering

Instrument Data Sheets

GA Drawings

Loop Diagrams

Logic Diagrams

Application Software Development

Interconnection /Hook-up Diagrams

Training forms an important & integral part of our value-added services. We strongly believe that well-trained Operations Staff are crucial to the successful start-up, operation and maintenance of any control system. After all, a control system - though valued at only a few percents of the overall cost- is the combined HEART & BRAIN of the process/plant.

Both classroom and hands-on training are provided to customer's engineers to ensure that they are up to a level where they can not only handle the equipment with confidence but are adequately familiar to provide at least up to the 1st level of support in the unlikely event of a system malfunction.

Apart from standard training programmes, customer and project-specific training tailored to meet individual or group needs are provided both in the factory and subsequently on the job site. Programs are available for both electronic and hydraulic control systems.

The HPU can be integrated into the common section of the panel complete with pneumatic/electric driven pumps, accumulators, reservoirs, thermal and pressure relief optimally sized to provide actuating power to all hydraulically operated shutdown valves.

Alternatively, the HPU can be a separate stand-alone skid mounted unit. Accumulators are available in different materials of construction to suit the environment.

Standard Features

Standard Features

From FPSOs and Production platforms to tunnels and buildings, C&E provides fire and gas detection, alarm and protection systems. Using state-of-the-art discrete as well as addressable detectors and transmitters, systems are configured to operate in conjunction with controller cards, addressable fire panels and/or plcs. Where required, we also supply the FM 200 or other extinguishing systems as part of the package.

Fire & Gas Systems are engineered and supplied on the stand-alone basis or as part of an integrated ESD and/or Process Control System.

Notable systems in successful operation include the F&G System for Saudi Aramco's ZULUF GOSP-2 Production Complex which, at 1.2 million/barrels per day, is the largest single such complex anywhere in the world. A significant number of FPSOs and production platforms worldwide are also protected by F&G systems designed and implemented by C & E.

ga

galfar

Sa

Saipem

B

B W Offshore

FM

FMC

PT

PT Tep

Mo

Modec

Pr

Prosafe

br

british Gas

Cl

Clough

ca

cairn

Mi

Mindef

AD

ADMA OPCO

Sa

Saudi Aramco

ON

ONGC

NP

NPCC

Za

Zadco

Ad

Adco

Mc

Mc Dermott

Dr

Dragon Oil

CN

CNOOC

l&

l&t

ga

galfar

Sa

Saipem

B

B W Offshore

FM

FMC

PT

PT Tep

Mo

Modec

Pr

Prosafe

br

british Gas

Cl

Clough

ca

cairn

Mi

Mindef

AD

ADMA OPCO

Sa

Saudi Aramco

ON

ONGC

NP

NPCC

Za

Zadco

Ad

Adco

Mc

Mc Dermott

Dr

Dragon Oil

CN

CNOOC

l&

l&t

ga

galfar

ga

galfar

Sa

Saipem

B

B W Offshore

FM

FMC

PT

PT Tep

Mo

Modec

Pr

Prosafe

br

british Gas

Cl

Clough

ca

cairn

Mi

Mindef

AD

ADMA OPCO

Sa

Saudi Aramco

ON

ONGC

NP

NPCC

Za

Zadco

Ad

Adco

Mc

Mc Dermott

Dr

Dragon Oil

CN

CNOOC

l&

l&t

ga

galfar

Sa

Saipem

B

B W Offshore

FM

FMC

PT

PT Tep

Mo

Modec

Pr

Prosafe

br

british Gas

Cl

Clough

ca

cairn

Mi

Mindef

AD

ADMA OPCO

Sa

Saudi Aramco

ON

ONGC

NP

NPCC

Za

Zadco

Ad

Adco

Mc

Mc Dermott

Dr

Dragon Oil

CN

CNOOC

l&

l&t

ga

galfar

Mr. Mr P Chakraborty

CEO

Mr Mr P Chakraborty

CEO

Mr Mr P Chakraborty

CEO

Mr Mr P Chakraborty

CEO

Mr Mr P Chakraborty

CEO

Mr Mr P Chakraborty

CEO

Mr Mr P Chakraborty

CEO

Mr Mr P Chakraborty

CEO

Mr Mr P Chakraborty

CEO

Mr Mr P Chakraborty

CEO

*Energy Dais does not guarantee the correctness of the information provided.

Benchmark yourself against your main competitors

Peek into the hidden marketing strategies of your competitors, across industries and

Keyword research made easy and based on actual traffic statistics

Discover new opportunities while reducing risk by learning from your competitor's mistakess

Outbrain has been using SimilarWeb for over a year and it's been instrumental for our ability to analyze our competitive environment, benchmark our performance, keep track of industry trends, and generate new leads.