Committed to providing the Industry with strong and reliable services.

PritamNagar 1st Slope, Opp. Medical Boys Hostel, Ellisbridge, Ahmedabad, Ahmedabad, India

PritamNagar 1st Slope, Opp. Medical Boys Hostel, Ellisbridge Ahmedabad , Gujarat, 380006,

Sebastian Joseph

Ph: +x xxxxxxxxxx

Email: xxxxxx@xxxx

( Click here to view contact)Share this Page

( Click here to view email and contact)

PritamNagar 1st Slope, Opp. Medical Boys Hostel

Ellisbridge

Contact Person : Sebastian Joseph

Ahmedabad , Gujarat,

380006, India

Ph: +x xxxxxxxxxx

Email: xxxxxx@xxxx

<ul> <li>Rig inspection is a critical component in drilling a well and it is an integral part of the preparation to spud a well.</li> <li>Interruptions in drilling operations due to improper or malfunctioning equipment is a cause of expensive NPT which is avoidable.</li> <li>Proper and appropriate rig inspections before acceptance of the rig, before the well is spud and follows up surveys during operations are critical to reduce downtime, increase reliability and safety and allow adequate environmental management and further to reduce NPT time-related costs.</li> <li>Tubestar, already in inspection business for more than 2 decades for tubular, handling equipment, DROPS etc integrated the Rig Inspection to the existing capabilities in Q4, 2012 through a team of highly experienced drilling personnel and inspectors</li> <li>Tubestar gained the rig inspection experience through a tie-up with Fact-O- Rig for the last 5 years</li> <li>Tubestar had developed a complete rig inspection package with systems, policies, procedures, inspection models such that a comprehensive inspection solution can be provided to the industry in a most effective manner.</li> <li>Tubestar rig inspectors are highly qualified drilling and maintenance personnel with a lot of direct hands-on experience in running and managing rigs and inspection of the rigs from construction to upgrade to operational management.</li> <li>Tubestar has a comprehensive rig inspection model to suit the requirements of both Operators to hire a rig or Rig Owners to upgrade/new construction/purchase/selling the rigs</li> <li>Tubestar Rig Inspection has the following range of inspection services: Conditional survey (a full conditional survey that provides accurate insight into the equipment status and condition and working systems, Fit for Purpose Acceptance Survey (depending upon the Client's objective, a fit for purpose survey confirms the functionality of the rig, systems, policies and procedures), Upgrade and New Construction (to be part of the Clients to ensure that the rig upgrade or new construction complies with all safety and operations standards), Compliance and Functionality Survey (to evaluate the compliance of the rig equipment, procedures and policies to the international acceptable standards and to confirm the functionality of the equipment according to the standards and design)<br />Value Evaluation and Selection Survey (to evaluate and value a rig for the purpose of either selling or purchasing as well as for banks/financial institutes to grant project loans and also to rank the rigs to create options to choose or select)</li> </ul> <p> </p>

<p>Rope access system (initially developed from the Mountaineering techniques) is a form of work positioning system which permits access to difficult to reach locations without use of Scaffolding, Cradles or Aerial platforms. Rope Access Technicians traverse on ropes to access work locations while suspended by their harness. This technique utilizes a backup fall arrest system which ensures redundancy. Rope access techniques have been used by the Industry for more than three decades and have an excellent safety track record.</p> <p>Advantages :</p> <ul> <li>Time-saving.</li> <li>Cost effective.</li> <li>Safe.</li> <li>Highly adaptable.</li> </ul> <p>Tubestar a front-runner in the Rope Access field offers complete Inspection, Maintenance and Repair services utilizing IRATA qualified technicians. IRATA safety procedures are being strictly adhered to. Compliance to ISO 22846-2:2012 & EN standards.</p> <p>Sectors coverage:</p> <ul> <li>Oil and Gas.</li> <li>Marine.</li> <li>Wind energy.</li> <li>Civil Infrastructure</li> <li>Power.</li> <li>Mega format advertising.</li> </ul>

<p>Tubestar is accredited with ABS for performing thickness gauging as part of a special periodic survey for mobile offshore drilling units. Our personnel have the necessary experience in various aspects of special survey and understand the special requirement survey to deliver accurate reports with tables and CAD drawings.</p> <ul> <li>Approved by ABS as a service supplier for thickness gauging – a constituent of intermediate and renewal special periodic surveys – part of class certification</li> <li>Thickness gauging on Low/ High-Pressure lines including mud lines, airlines, ballast lines, choke and kill lines/manifolds etc</li> <li>UT Shearwave inspection for internal defects.</li> </ul> <p> </p>

<p>"Tubetrack" was conceived as an alternate reporting format to help the Industry keep track of its tubular in a much efficient manner, the Industry with its challenges on day to day basis had to have information instant which saves COST for all involved.</p> <p>Tubular reports, a vital input to a successful drilling campaign had its difficulties with conventional reporting which resulted in a number of sheets, where keeping track of your vital asset was rather impossible and cumbersome.</p> <p>Tubetrack resolves issues considerably offering a Client a relatively Paper free environment and better tracking of its tubular – a fact truly appreciated by Industry Majors.</p> <p><br /><strong>Features</strong></p> <ul> <li>Web-based reporting system for Drill pipe / Drill collar / HWDP / Lifting Gear and</li> <li>Drops Survey</li> <li>Accessible anytime anywhere through a web browser</li> <li>Rig personnel can download signed reports and help in managing paperwork</li> <li>Gives client access to the complete history of inspection of each tubular inspected.</li> <li>Inspections can be planned advance as it gives details of tubular getting due for inspection</li> <li>Exhaustive query based reporting to find out pipes matching certain criteria this can help inventory planning i.e. purchase of new tubular</li> <li>Web-based reporting system for other reports like MPI, LPT, UT, Load Testing, Lifting Gear Inspections and DROPS Surveys</li> <li>History of all previous reports kept in the system to access it anytime anywhere</li> <li>Signed reports are uploaded and maintained in the system</li> </ul> <p> </p>

<p>Bottom Hole Assembly (BHA) inspections are carried out as per the latest editions of API and DS-1 (3-5) guidelines.</p> <p>BHA inspections services include:</p> <p>1. Visual Inspections<br />2. Thread Gauging<br />3. Wet and Dry Magnetic Particle Inspection<br />4. Dimensional Inspection</p> <p>Optional service of refacing if required can be provided.</p>

<p><strong>Cargo Handling</strong></p> <ul> <li>Inspection and recertification of Containers / Baskets and Pallets</li> <li>Proof Load Testing Services</li> </ul> <p>Load testing is carried out by competent inspectors who are competent as per local regulations or qualified by LEEA / NSL. In addition, they are certified to ASNT Level II. Tubestar has an in-house testing facility with tensile test beds for pull testing of loose lifting equipment like slings, shackles etc up to 100 Tons. We have customized hydraulic jacking units to load test pad eyes offshore up to 30 Tons. Hydraulic jacking unit is mounted on the pad eyes and load tested at required proof loads.</p>

<p>Inspection of used casing or tubing is carried out in accordance with API Spec 5CT and the general scope shall include:</p> <ul> <li>OD Blasting</li> <li>ID Cleaning</li> <li>Spot Wall Thickness Measurements</li> <li>Grade Sorting</li> <li>EMI on Body (Tubing)</li> <li>Visual Thread Inspection</li> <li>Full-Length Drifting</li> <li>Black Light Inspections</li> <li>Hydraulic Pressure Testing</li> <li>Bucking Services</li> </ul>

<p>Tubestar's experienced technicians conduct the crane inspection in accordance with API RD 2D standards and provide recommendations for repair or further inspections. Static and Dynamic load testing is performed as per requirement and Tubestar can mobilize calibrated load cells and waterbags at short notice to carry out Crane load testing.</p>

<p>Tubestar has completed numerous inspections for Derrick as per API RP 4G guidelines – which is the recommended practices for use and procedure for inspection, maintenance and repair of drilling and well-servicing structures. Qualified personnel will carry out derrick inspection (Category III) survey in line with API RP 4G. Inspection focuses on load bearing components and members to determine the condition of mast/derrick and substructure. A comprehensive report as per the template of API RP 4G is prepared and submitted to the client with recommendations. Rope access technics complement the inspection for Derrick bolt checks etc.</p> <p>The thorough inspection process covers:</p> <ul> <li>Gin pole construction, including platforms, ladders, braces safety gates, connection plates, bolts and fasteners</li> <li>Upper and lower sections of the derrick stem, including all platforms, ladders, braces safety gates, connection plates, bolts and fasteners</li> <li>Dolly track, including all Y-frame support beams, beam clamps and joint couplings</li> <li>Dolly carriage guide rails, including upper, middle and lower sections</li> <li>Racking board area, including the support frames, fingers straightness, latches, fingerboard access and all bolts and fasteners</li> <li>Racking system, including all racking board supports, platforms and system supports</li> <li>Derrick outfitting, including wind walls and any pipewort, such as vent lines or HP mud lines</li> <li>Derrick safety slings and lifting equipment</li> <li>Derrick structure footings</li> <li>Derrick structural general condition</li> <li>Percentage bolt tightness check – if required</li> </ul>

<p>Tubestar can provide a full range of pipe inspection ion sizes ranging from 2-3/8" to 6.5/8" while following customer's specifications and edition of DS-1 or API guidelines. We have state-of-the-art tube inspection equipment to meet API inspection requirements or third-party inspections, including a full-length wall thickness measurement of the pipe tubes. Also have various types of EMI of units, conventional ones as well as dual-function units with wall monitoring. Drill Pipe</p> <p>Inspection services include:</p> <ul> <li>Visual body and thread inspection</li> <li>UT Thickness Gauging</li> <li>Thread gauging</li> <li>End Area Inspections</li> <li>Electromagnetic Inspection (EMI)</li> <li>Ultrasonic Inspection On End Area</li> <li>Wet and Dry Magnetic Particle Inspection</li> <li>Dimensional Inspection</li> </ul> <p>We also can provide refacing, straightening and pipe internal and external cleaning services.</p>

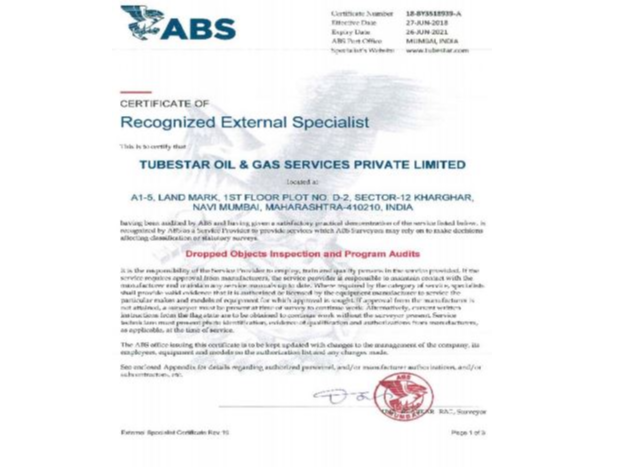

<p><strong>Drops Object Survey</strong></p> <p>Tubestar is a member of the DROPS forum and supports the aims and objectives of the UK's Dropped Objects Prevention Scheme (DROPS). Dropped Object Surveys and Inspections are a key element of dropped object control and prevention management systems.</p> <p>Tubestar can help prevent a potential dropped object becoming another unwelcome safety statistic by conducting detailed dropped object survey of hazardous areas. We are all committed to preventing harm to personnel and damage to equipment from dropped objects. Tubestar provides qualified inspectors to conduct a thorough dropped object survey of the derrick and other areas as required.</p> <p>All the areas which are to be inspected are divided into different zones and are surveyed as per Client's dropped object policy. All the findings are recorded in the report with photographic evidence and corrective actions for the same. The report is divided into two parts, one is the Inspection Survey which includes all observations and another is the Failed Items list which covers the items which failed in the survey.</p> <p>Generally, Survey tasks are:</p> <ul> <li>Document equipment location by Inspection Area</li> <li>Photograph each item surveyed</li> <li>Include unique identification number to each item (tag numbers)</li> <li>Describe each item surveyed</li> <li>Inspect and document Primary Securing method(s)</li> <li>Inspect and document the Secondary Retention method(s)</li> <li>Record equipment condition as Pass or Fail, including comments (ie Satisfactory or Reason for Failure)</li> <li>Record inspection frequency (ie weekly, monthly) as recorded in the Equipment Family Inspection Criteria</li> <li>Generate a Failed Items List</li> </ul> <p>Dropped objects pose a significant threat to personal safety; they also have the potential to cause damage to structures, plant and equipment leading to loss of containment and consequential release to the environment.</p> <p> </p>

<p>More and more companies are opting to go in for Eddy current inspection due to inherent benefit of non-requirement of paint removal for inspection which is a drawback in the conventional NDT method of MPI. Eddy current eliminates the need for surface preparation and saves a lot of time in paint removal and re-application of paint post inspection. Only at places, indications received prove-up is done with MPI.</p> <p>One of the major advantages of eddy current as an NDT tool is the variety of inspections and measurements that can be performed. In the proper circumstances, eddy currents can be used for:</p> <ul> <li>Crack detection</li> <li>Material thickness measurements</li> <li>Coating thickness measurements</li> <li>Conductivity measurements for Material identification, Heat damage detection, Case depth determination, Heat treatment monitoring.</li> </ul> <p>Some of the advantages of Eddy current inspection include:</p> <ul> <li>Sensitive to small cracks and other defects</li> <li>Detects surface and near-surface defects</li> <li>The inspection gives immediate results</li> <li>Equipment is very portable. The method can be used for much more than flaw detection.</li> <li>Minimum part preparation is required</li> <li>Test probe does not need to contact the part</li> <li>Inspects complex shapes and sizes of conductive materials</li> <li>Tubestar has onboard trained and qualified inspectors to carry out Eddy current inspection onshore and offshore.</li> <li>Tubestar uses the latest state of the art Phasec-3D unit from GE for inspection.</li> </ul>

<p>Tubestar can inspect, test and certify all types of lifting appliances on location. We are a member of LEEA in the UK and follow the latest LOLER guidelines. These surveys provide a comprehensive register and database of all hoisting and lifting equipment on a drilling rig and include both fixed and loose lifting gears. All the equipment are inspected to the latest standards of LOLER / API / BS and manufacturers guidelines wherever applicable.</p>

<ul> <li>Rig inspection is a critical component in drilling a well and it is an integral part of the preparation to spud a well.</li> <li>Interruptions in drilling operations due to improper or malfunctioning equipment is a cause of expensive NPT which is avoidable.</li> <li>Proper and appropriate rig inspections before acceptance of the rig, before the well is spud and follows up surveys during operations are critical to reduce downtime, increase reliability and safety and allow adequate environmental management and further to reduce NPT time-related costs.</li> <li>Tubestar, already in inspection business for more than 2 decades for tubular, handling equipment, DROPS etc integrated the Rig Inspection to the existing capabilities in Q4, 2012 through a team of highly experienced drilling personnel and inspectors</li> <li>Tubestar gained the rig inspection experience through a tie-up with Fact-O- Rig for the last 5 years</li> <li>Tubestar had developed a complete rig inspection package with systems, policies, procedures, inspection models such that a comprehensive inspection solution can be provided to the industry in a most effective manner.</li> <li>Tubestar rig inspectors are highly qualified drilling and maintenance personnel with a lot of direct hands-on experience in running and managing rigs and inspection of the rigs from construction to upgrade to operational management.</li> <li>Tubestar has a comprehensive rig inspection model to suit the requirements of both Operators to hire a rig or Rig Owners to upgrade/new construction/purchase/selling the rigs</li> <li>Tubestar Rig Inspection has the following range of inspection services: Conditional survey (a full conditional survey that provides accurate insight into the equipment status and condition and working systems, Fit for Purpose Acceptance Survey (depending upon the Client's objective, a fit for purpose survey confirms the functionality of the rig, systems, policies and procedures), Upgrade and New Construction (to be part of the Clients to ensure that the rig upgrade or new construction complies with all safety and operations standards), Compliance and Functionality Survey (to evaluate the compliance of the rig equipment, procedures and policies to the international acceptable standards and to confirm the functionality of the equipment according to the standards and design)<br />Value Evaluation and Selection Survey (to evaluate and value a rig for the purpose of either selling or purchasing as well as for banks/financial institutes to grant project loans and also to rank the rigs to create options to choose or select)</li> </ul> <p> </p>

<p>Rope access system (initially developed from the Mountaineering techniques) is a form of work positioning system which permits access to difficult to reach locations without use of Scaffolding, Cradles or Aerial platforms. Rope Access Technicians traverse on ropes to access work locations while suspended by their harness. This technique utilizes a backup fall arrest system which ensures redundancy. Rope access techniques have been used by the Industry for more than three decades and have an excellent safety track record.</p> <p>Advantages :</p> <ul> <li>Time-saving.</li> <li>Cost effective.</li> <li>Safe.</li> <li>Highly adaptable.</li> </ul> <p>Tubestar a front-runner in the Rope Access field offers complete Inspection, Maintenance and Repair services utilizing IRATA qualified technicians. IRATA safety procedures are being strictly adhered to. Compliance to ISO 22846-2:2012 & EN standards.</p> <p>Sectors coverage:</p> <ul> <li>Oil and Gas.</li> <li>Marine.</li> <li>Wind energy.</li> <li>Civil Infrastructure</li> <li>Power.</li> <li>Mega format advertising.</li> </ul>

<p>Tubestar is accredited with ABS for performing thickness gauging as part of a special periodic survey for mobile offshore drilling units. Our personnel have the necessary experience in various aspects of special survey and understand the special requirement survey to deliver accurate reports with tables and CAD drawings.</p> <ul> <li>Approved by ABS as a service supplier for thickness gauging – a constituent of intermediate and renewal special periodic surveys – part of class certification</li> <li>Thickness gauging on Low/ High-Pressure lines including mud lines, airlines, ballast lines, choke and kill lines/manifolds etc</li> <li>UT Shearwave inspection for internal defects.</li> </ul> <p> </p>

<p>"Tubetrack" was conceived as an alternate reporting format to help the Industry keep track of its tubular in a much efficient manner, the Industry with its challenges on day to day basis had to have information instant which saves COST for all involved.</p> <p>Tubular reports, a vital input to a successful drilling campaign had its difficulties with conventional reporting which resulted in a number of sheets, where keeping track of your vital asset was rather impossible and cumbersome.</p> <p>Tubetrack resolves issues considerably offering a Client a relatively Paper free environment and better tracking of its tubular – a fact truly appreciated by Industry Majors.</p> <p><br /><strong>Features</strong></p> <ul> <li>Web-based reporting system for Drill pipe / Drill collar / HWDP / Lifting Gear and</li> <li>Drops Survey</li> <li>Accessible anytime anywhere through a web browser</li> <li>Rig personnel can download signed reports and help in managing paperwork</li> <li>Gives client access to the complete history of inspection of each tubular inspected.</li> <li>Inspections can be planned advance as it gives details of tubular getting due for inspection</li> <li>Exhaustive query based reporting to find out pipes matching certain criteria this can help inventory planning i.e. purchase of new tubular</li> <li>Web-based reporting system for other reports like MPI, LPT, UT, Load Testing, Lifting Gear Inspections and DROPS Surveys</li> <li>History of all previous reports kept in the system to access it anytime anywhere</li> <li>Signed reports are uploaded and maintained in the system</li> </ul> <p> </p>

<p>Bottom Hole Assembly (BHA) inspections are carried out as per the latest editions of API and DS-1 (3-5) guidelines.</p> <p>BHA inspections services include:</p> <p>1. Visual Inspections<br />2. Thread Gauging<br />3. Wet and Dry Magnetic Particle Inspection<br />4. Dimensional Inspection</p> <p>Optional service of refacing if required can be provided.</p>

<p><strong>Cargo Handling</strong></p> <ul> <li>Inspection and recertification of Containers / Baskets and Pallets</li> <li>Proof Load Testing Services</li> </ul> <p>Load testing is carried out by competent inspectors who are competent as per local regulations or qualified by LEEA / NSL. In addition, they are certified to ASNT Level II. Tubestar has an in-house testing facility with tensile test beds for pull testing of loose lifting equipment like slings, shackles etc up to 100 Tons. We have customized hydraulic jacking units to load test pad eyes offshore up to 30 Tons. Hydraulic jacking unit is mounted on the pad eyes and load tested at required proof loads.</p>

Drops Object Survey

Tubestar is a member of the DROPS forum and supports the aims and objectives of the UK's Dropped Objects Prevention Scheme (DROPS). Dropped Object Surveys and Inspections are a key element of dropped object control and prevention management systems.

Tubestar can help prevent a potential dropped object becoming another unwelcome safety statistic by conducting detailed dropped object survey of hazardous areas. We are all committed to preventing harm to personnel and damage to equipment from dropped objects. Tubestar provides qualified inspectors to conduct a thorough dropped object survey of the derrick and other areas as required.

All the areas which are to be inspected are divided into different zones and are surveyed as per Client's dropped object policy. All the findings are recorded in the report with photographic evidence and corrective actions for the same. The report is divided into two parts, one is the Inspection Survey which includes all observations and another is the Failed Items list which covers the items which failed in the survey.

Generally, Survey tasks are:

Dropped objects pose a significant threat to personal safety; they also have the potential to cause damage to structures, plant and equipment leading to loss of containment and consequential release to the environment.

More and more companies are opting to go in for Eddy current inspection due to inherent benefit of non-requirement of paint removal for inspection which is a drawback in the conventional NDT method of MPI. Eddy current eliminates the need for surface preparation and saves a lot of time in paint removal and re-application of paint post inspection. Only at places, indications received prove-up is done with MPI.

One of the major advantages of eddy current as an NDT tool is the variety of inspections and measurements that can be performed. In the proper circumstances, eddy currents can be used for:

Some of the advantages of Eddy current inspection include:

Tubestar can inspect, test and certify all types of lifting appliances on location. We are a member of LEEA in the UK and follow the latest LOLER guidelines. These surveys provide a comprehensive register and database of all hoisting and lifting equipment on a drilling rig and include both fixed and loose lifting gears. All the equipment are inspected to the latest standards of LOLER / API / BS and manufacturers guidelines wherever applicable.

Rope access system (initially developed from the Mountaineering techniques) is a form of work positioning system which permits access to difficult to reach locations without use of Scaffolding, Cradles or Aerial platforms. Rope Access Technicians traverse on ropes to access work locations while suspended by their harness. This technique utilizes a backup fall arrest system which ensures redundancy. Rope access techniques have been used by the Industry for more than three decades and have an excellent safety track record.

Advantages :

Tubestar a front-runner in the Rope Access field offers complete Inspection, Maintenance and Repair services utilizing IRATA qualified technicians. IRATA safety procedures are being strictly adhered to. Compliance to ISO 22846-2:2012 & EN standards.

Sectors coverage:

Tubestar is accredited with ABS for performing thickness gauging as part of a special periodic survey for mobile offshore drilling units. Our personnel have the necessary experience in various aspects of special survey and understand the special requirement survey to deliver accurate reports with tables and CAD drawings.

"Tubetrack" was conceived as an alternate reporting format to help the Industry keep track of its tubular in a much efficient manner, the Industry with its challenges on day to day basis had to have information instant which saves COST for all involved.

Tubular reports, a vital input to a successful drilling campaign had its difficulties with conventional reporting which resulted in a number of sheets, where keeping track of your vital asset was rather impossible and cumbersome.

Tubetrack resolves issues considerably offering a Client a relatively Paper free environment and better tracking of its tubular – a fact truly appreciated by Industry Majors.

Features

Bottom Hole Assembly (BHA) inspections are carried out as per the latest editions of API and DS-1 (3-5) guidelines.

BHA inspections services include:

1. Visual Inspections

2. Thread Gauging

3. Wet and Dry Magnetic Particle Inspection

4. Dimensional Inspection

Optional service of refacing if required can be provided.

Cargo Handling

Load testing is carried out by competent inspectors who are competent as per local regulations or qualified by LEEA / NSL. In addition, they are certified to ASNT Level II. Tubestar has an in-house testing facility with tensile test beds for pull testing of loose lifting equipment like slings, shackles etc up to 100 Tons. We have customized hydraulic jacking units to load test pad eyes offshore up to 30 Tons. Hydraulic jacking unit is mounted on the pad eyes and load tested at required proof loads.

Inspection of used casing or tubing is carried out in accordance with API Spec 5CT and the general scope shall include:

Tubestar's experienced technicians conduct the crane inspection in accordance with API RD 2D standards and provide recommendations for repair or further inspections. Static and Dynamic load testing is performed as per requirement and Tubestar can mobilize calibrated load cells and waterbags at short notice to carry out Crane load testing.

Tubestar has completed numerous inspections for Derrick as per API RP 4G guidelines – which is the recommended practices for use and procedure for inspection, maintenance and repair of drilling and well-servicing structures. Qualified personnel will carry out derrick inspection (Category III) survey in line with API RP 4G. Inspection focuses on load bearing components and members to determine the condition of mast/derrick and substructure. A comprehensive report as per the template of API RP 4G is prepared and submitted to the client with recommendations. Rope access technics complement the inspection for Derrick bolt checks etc.

The thorough inspection process covers:

Tubestar can provide a full range of pipe inspection ion sizes ranging from 2-3/8" to 6.5/8" while following customer's specifications and edition of DS-1 or API guidelines. We have state-of-the-art tube inspection equipment to meet API inspection requirements or third-party inspections, including a full-length wall thickness measurement of the pipe tubes. Also have various types of EMI of units, conventional ones as well as dual-function units with wall monitoring. Drill Pipe

Inspection services include:

We also can provide refacing, straightening and pipe internal and external cleaning services.

Drops Object Survey

Tubestar is a member of the DROPS forum and supports the aims and objectives of the UK's Dropped Objects Prevention Scheme (DROPS). Dropped Object Surveys and Inspections are a key element of dropped object control and prevention management systems.

Tubestar can help prevent a potential dropped object becoming another unwelcome safety statistic by conducting detailed dropped object survey of hazardous areas. We are all committed to preventing harm to personnel and damage to equipment from dropped objects. Tubestar provides qualified inspectors to conduct a thorough dropped object survey of the derrick and other areas as required.

All the areas which are to be inspected are divided into different zones and are surveyed as per Client's dropped object policy. All the findings are recorded in the report with photographic evidence and corrective actions for the same. The report is divided into two parts, one is the Inspection Survey which includes all observations and another is the Failed Items list which covers the items which failed in the survey.

Generally, Survey tasks are:

Dropped objects pose a significant threat to personal safety; they also have the potential to cause damage to structures, plant and equipment leading to loss of containment and consequential release to the environment.

More and more companies are opting to go in for Eddy current inspection due to inherent benefit of non-requirement of paint removal for inspection which is a drawback in the conventional NDT method of MPI. Eddy current eliminates the need for surface preparation and saves a lot of time in paint removal and re-application of paint post inspection. Only at places, indications received prove-up is done with MPI.

One of the major advantages of eddy current as an NDT tool is the variety of inspections and measurements that can be performed. In the proper circumstances, eddy currents can be used for:

Some of the advantages of Eddy current inspection include:

Tubestar can inspect, test and certify all types of lifting appliances on location. We are a member of LEEA in the UK and follow the latest LOLER guidelines. These surveys provide a comprehensive register and database of all hoisting and lifting equipment on a drilling rig and include both fixed and loose lifting gears. All the equipment are inspected to the latest standards of LOLER / API / BS and manufacturers guidelines wherever applicable.

Rope access system (initially developed from the Mountaineering techniques) is a form of work positioning system which permits access to difficult to reach locations without use of Scaffolding, Cradles or Aerial platforms. Rope Access Technicians traverse on ropes to access work locations while suspended by their harness. This technique utilizes a backup fall arrest system which ensures redundancy. Rope access techniques have been used by the Industry for more than three decades and have an excellent safety track record.

Advantages :

Tubestar a front-runner in the Rope Access field offers complete Inspection, Maintenance and Repair services utilizing IRATA qualified technicians. IRATA safety procedures are being strictly adhered to. Compliance to ISO 22846-2:2012 & EN standards.

Sectors coverage:

Tubestar is accredited with ABS for performing thickness gauging as part of a special periodic survey for mobile offshore drilling units. Our personnel have the necessary experience in various aspects of special survey and understand the special requirement survey to deliver accurate reports with tables and CAD drawings.

"Tubetrack" was conceived as an alternate reporting format to help the Industry keep track of its tubular in a much efficient manner, the Industry with its challenges on day to day basis had to have information instant which saves COST for all involved.

Tubular reports, a vital input to a successful drilling campaign had its difficulties with conventional reporting which resulted in a number of sheets, where keeping track of your vital asset was rather impossible and cumbersome.

Tubetrack resolves issues considerably offering a Client a relatively Paper free environment and better tracking of its tubular – a fact truly appreciated by Industry Majors.

Features

Bottom Hole Assembly (BHA) inspections are carried out as per the latest editions of API and DS-1 (3-5) guidelines.

BHA inspections services include:

1. Visual Inspections

2. Thread Gauging

3. Wet and Dry Magnetic Particle Inspection

4. Dimensional Inspection

Optional service of refacing if required can be provided.

Cargo Handling

Load testing is carried out by competent inspectors who are competent as per local regulations or qualified by LEEA / NSL. In addition, they are certified to ASNT Level II. Tubestar has an in-house testing facility with tensile test beds for pull testing of loose lifting equipment like slings, shackles etc up to 100 Tons. We have customized hydraulic jacking units to load test pad eyes offshore up to 30 Tons. Hydraulic jacking unit is mounted on the pad eyes and load tested at required proof loads.

Inspection of used casing or tubing is carried out in accordance with API Spec 5CT and the general scope shall include:

Tubestar's experienced technicians conduct the crane inspection in accordance with API RD 2D standards and provide recommendations for repair or further inspections. Static and Dynamic load testing is performed as per requirement and Tubestar can mobilize calibrated load cells and waterbags at short notice to carry out Crane load testing.

Tubestar has completed numerous inspections for Derrick as per API RP 4G guidelines – which is the recommended practices for use and procedure for inspection, maintenance and repair of drilling and well-servicing structures. Qualified personnel will carry out derrick inspection (Category III) survey in line with API RP 4G. Inspection focuses on load bearing components and members to determine the condition of mast/derrick and substructure. A comprehensive report as per the template of API RP 4G is prepared and submitted to the client with recommendations. Rope access technics complement the inspection for Derrick bolt checks etc.

The thorough inspection process covers:

Tubestar can provide a full range of pipe inspection ion sizes ranging from 2-3/8" to 6.5/8" while following customer's specifications and edition of DS-1 or API guidelines. We have state-of-the-art tube inspection equipment to meet API inspection requirements or third-party inspections, including a full-length wall thickness measurement of the pipe tubes. Also have various types of EMI of units, conventional ones as well as dual-function units with wall monitoring. Drill Pipe

Inspection services include:

We also can provide refacing, straightening and pipe internal and external cleaning services.

Drops Object Survey

Tubestar is a member of the DROPS forum and supports the aims and objectives of the UK's Dropped Objects Prevention Scheme (DROPS). Dropped Object Surveys and Inspections are a key element of dropped object control and prevention management systems.

Tubestar can help prevent a potential dropped object becoming another unwelcome safety statistic by conducting detailed dropped object survey of hazardous areas. We are all committed to preventing harm to personnel and damage to equipment from dropped objects. Tubestar provides qualified inspectors to conduct a thorough dropped object survey of the derrick and other areas as required.

All the areas which are to be inspected are divided into different zones and are surveyed as per Client's dropped object policy. All the findings are recorded in the report with photographic evidence and corrective actions for the same. The report is divided into two parts, one is the Inspection Survey which includes all observations and another is the Failed Items list which covers the items which failed in the survey.

Generally, Survey tasks are:

Dropped objects pose a significant threat to personal safety; they also have the potential to cause damage to structures, plant and equipment leading to loss of containment and consequential release to the environment.

We

Weatherford

Ha

Halliburton

Ba

Baker Hughes

Ag

Aggrego

Ar

Arabian Drilling Co.

Da

Dalma Energy

Ku

Kuwait Drilling Company

WD

WDI

NA

NAPESCO

vE

vESTAS

ga

gamesa

Su

Suzlon

Si

Siemens Gamesa

RC

RCF

Bh

Bharat petroleum corporation limited

ON

ONGC

tr

transocean

Ca

Cairn

Re

Relaince

Sh

Shelf Drilling

Va

Vantage

Pa

Paragon Offshore

GS

GSPC

Ab

Aban

Ak

Aker

Oi

Oil India Limited

Ji

Jindal

NA

NABORS

ES

ESSAR

Sc

Schlumberger

We

Weatherford

Ha

Halliburton

Ba

Baker Hughes

Ag

Aggrego

Ar

Arabian Drilling Co.

Da

Dalma Energy

Ku

Kuwait Drilling Company

WD

WDI

NA

NAPESCO

vE

vESTAS

ga

gamesa

Su

Suzlon

Si

Siemens Gamesa

RC

RCF

Bh

Bharat petroleum corporation limited

ON

ONGC

tr

transocean

Ca

Cairn

Re

Relaince

Sh

Shelf Drilling

Va

Vantage

Pa

Paragon Offshore

GS

GSPC

Ab

Aban

Ak

Aker

Oi

Oil India Limited

Ji

Jindal

NA

NABORS

ES

ESSAR

Sc

Schlumberger

We

Weatherford

Ha

Halliburton

Ba

Baker Hughes

Ag

Aggrego

Ar

Arabian Drilling Co.

Da

Dalma Energy

Ku

Kuwait Drilling Company

WD

WDI

NA

NAPESCO

vE

vESTAS

ga

gamesa

Su

Suzlon

Si

Siemens Gamesa

RC

RCF

Bh

Bharat petroleum corporation limited

ON

ONGC

tr

transocean

Ca

Cairn

Re

Relaince

Sh

Shelf Drilling

Va

Vantage

Pa

Paragon Offshore

GS

GSPC

Ab

Aban

Ak

Aker

Oi

Oil India Limited

Ji

Jindal

NA

NABORS

ES

ESSAR

Sc

Schlumberger

We

Weatherford

Ha

Halliburton

Ba

Baker Hughes

Ag

Aggrego

Ar

Arabian Drilling Co.

Da

Dalma Energy

Ku

Kuwait Drilling Company

WD

WDI

NA

NAPESCO

vE

vESTAS

ga

gamesa

Su

Suzlon

Si

Siemens Gamesa

RC

RCF

Bh

Bharat petroleum corporation limited

ON

ONGC

tr

transocean

Ca

Cairn

Re

Relaince

Sh

Shelf Drilling

Va

Vantage

Pa

Paragon Offshore

GS

GSPC

Ab

Aban

Ak

Aker

Oi

Oil India Limited

Ji

Jindal

NA

NABORS

ES

ESSAR

Sc

Schlumberger

*Energy Dais does not guarantee the correctness of the information provided.

Benchmark yourself against your main competitors

Peek into the hidden marketing strategies of your competitors, across industries and

Keyword research made easy and based on actual traffic statistics

Discover new opportunities while reducing risk by learning from your competitor's mistakess

Outbrain has been using SimilarWeb for over a year and it's been instrumental for our ability to analyze our competitive environment, benchmark our performance, keep track of industry trends, and generate new leads.